Overcoming cell therapy manufacturing bottlenecks

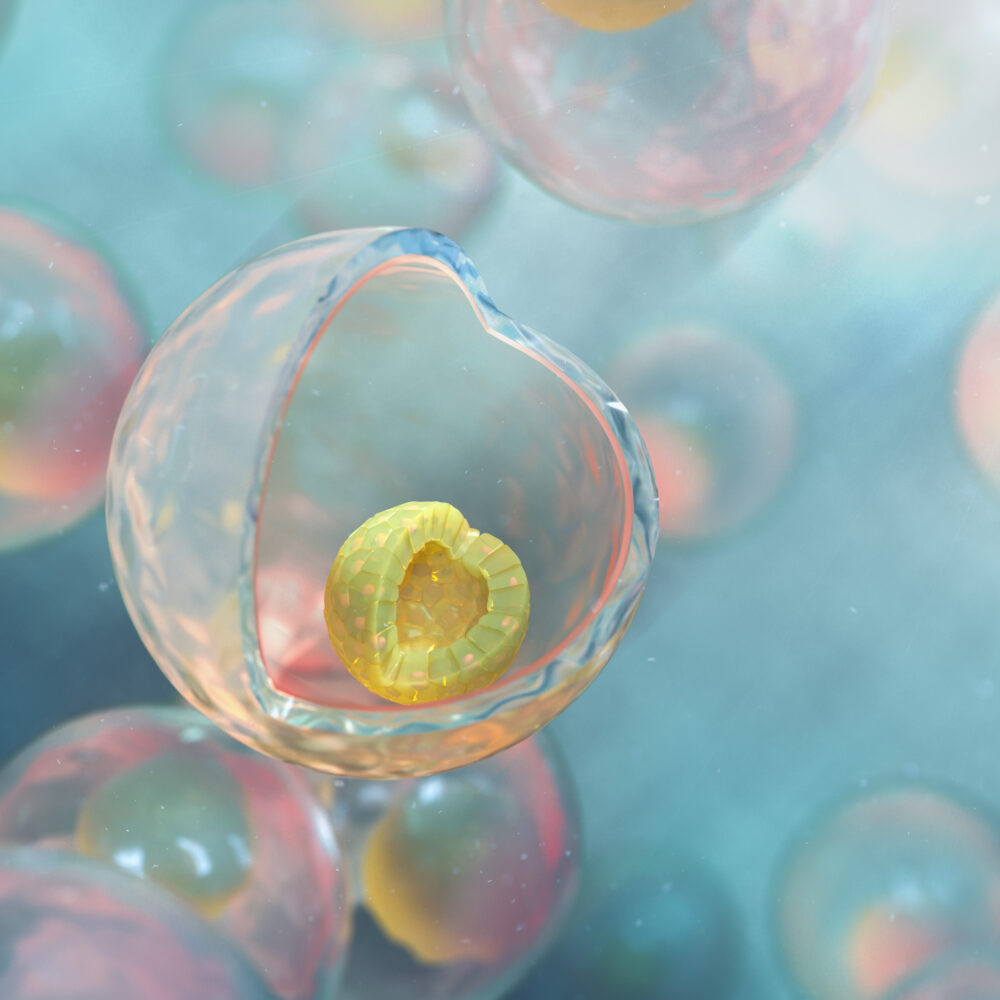

C-Stem™ is a biomimetic cell culture platform allowing for the mass-production of stem cell- derived therapies with unprecedented cell quality.

Scale-up

C-Stem™ generates scale-independent cell culture micro-environments, allowing to progress to larger bioreactors without changing key parameters.

Safety

C-Stem™ perserves genomic integrity and yields mature cell phenotypes, thereby enhancing the safety of cellular products

Efficacy

C-Stem™ delivers functional microtissues, which were shown to improve graft integration and reduce time-to-effect.

Step-by-step

The C-Stem™ process

#1 industrial-grade microfluidics

High-throughput stem cell encapsulation

- GMP encapsulation device

- Automated, closed, single-use

- Throughput: > 1,000 capsules per second

#2 biomimetic 3D micro-environments

Self-organization in in vivo-like stem cell microtissues

- Epiblast structure promotes fast & high-fidelity cell division

- Capsule lets nutrients, gas and growth factors in & out

- Capsule protects cellular content from mechanical stress

#3 Bioreactor scale-up

Exponential stem cell expansion & differentiation in bioreactors

- >100-fold hPSC amplification per week

- Best-in-class cell viability, pluripotency & genomic integrity

- Single-batches of over 10 billion cells in 10L bioreactor

- Differentiation into functional microtissues in bioreactor

PARTNERSHIP MODEL

Our job: to bring the benefits of C-Stem™ as fast as possible to patients through in-house programs and strategic alliances.

Adapt 2D to 3D

Our 3D stem cell biology team dedicated R&D platform can adapt existing protocols to C-Stem™ for optimal hPSC amplification and differentiation

Scale-up early

Our bioproduction team can develop bioreactor-based manufacturing processes to secure commercial-scale batches for non-clinical and early clinical phases

Enhance delivery

Our scientists can provide expertise in logistics, delivery formats and medical devices to maximize the clinical convenience and therapeutic benefits of the product

Optimize manufacturing

Our encapsulation and analytical development teams can provide continuous support for the optimization of manufacturing processes

Partner with us

Contact our team !

C-Stem™ technology: Scaling-up iPS-derived cell therapy manufacturing in bioreactors

TreeFrog Therapeutics has developed C-Stem, a technology allowing for the mass-production of iPS-derived cell therapies in large-scale bioreactors. C-stem is based on a proprietary high-throughput cell encapsulation technology which generates over 1,000 capsules per second. Each stem cell capsule constitutes a biomimetic micro-environment which recapitulates an in-vivo like stem cell niche. In the capsule, pluripotent stem cells self-organize to form an epiblast-like 3D stem cell microtissue which promotes exponential pluripotent stem cell growth, maintenance of homogenous pluripotency and high-fidelity chromosome segregation (preservation of genomic integrity). But the capsule is also protecting stem cells during manufacturing proceses. In fact, C-Stem allows for the scale-independent exponential amplification of hiPSCs and their differentiation into functional 3D microtissues in industrial bioreactors.