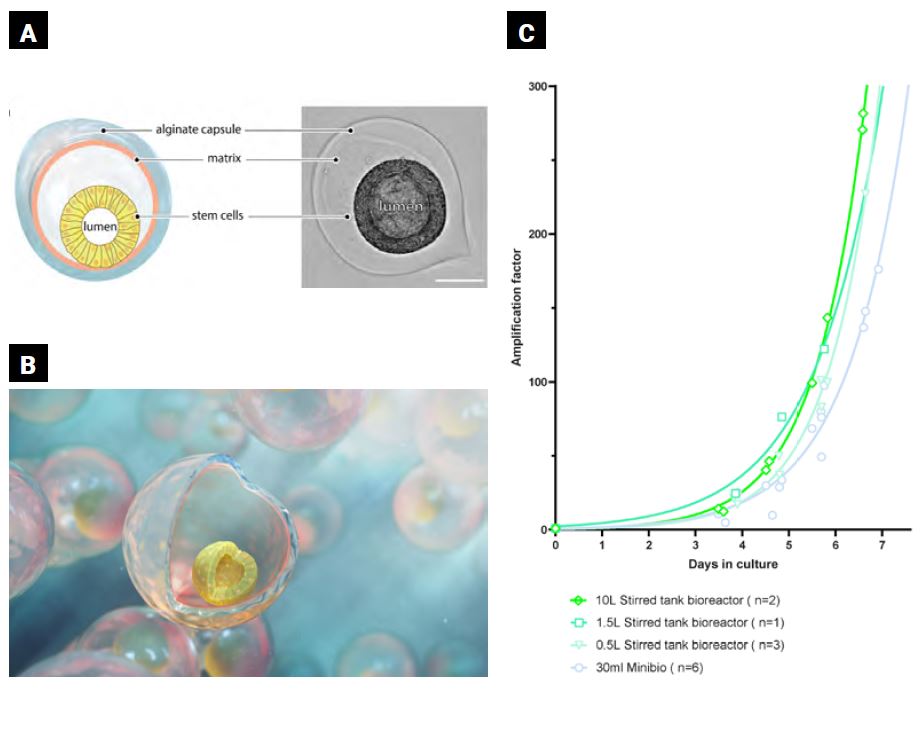

The lumenized rosette conformation is critical to the behavior of hPSCs in vivo. Replicating this architecture seems a logical approach to achieve in vivo-like exponential growth while preserving cell quality. However, current protocols for hPSC culture in lumenized rosette conformation were not designed for scale-up. The C-Stem™ platform was invented to fill this gap.

TreeFrog Therapeutics’ GMP cell encapsulation platform

Biomimetic capsules

The C-Stem™ technology utilizes proprietary microfluidics to encapsulate hPSC in hollow alginate shells at very high throughput (> 1000 capsules per second). The inner wall of the capsule is decorated with extracellular matrix, thus mimicking the basement membrane of the hPSC niche. In this biomimetic microenvironment, hPSCs spontaneously self-organize in 3D and form in vivo-like lumenized rosette structures. The size of the capsule (tunable from 100 to 800 μm diameter) and the porosity of the alginate allow for optimal diffusion of oxygen and nutrients, thus preventing the formation of a necrotic core. On the outside, the 30 μm thick wall of alginate constitutes a highly resistant shell, which protects PSCs from hydrodynamic stress. When the capsule reaches confluence, the PSC colony is easily harvested, simply by dissolving the alginate shell with a calcium chelator.

C-Stem™-enabled encapsulation preserves the exponential expansion profile of hPSCs grown in rosette conformation regardless of the bioreactor volume (Cohen et al., 2023)

Bioreactor scale-up

Widely used to scale-up bioproduction processes, stirred-tank bioreactors provide full control over key cell culture parameters, such as pH, temperature, oxygen level, and media change regimens. So far, the obvious benefits of bioreactors to finely replicate the in vivo conditions of hPSCs were limited by impeller-induced shear stress, causing significant cell death and spontaneous differentiation. By shielding hPSCs within alginate capsules, the C-Stem™ technology removes the hydrodynamic stress constraints, thus permitting biomimetic hPSC culture within large-scale industrial bioreactors.

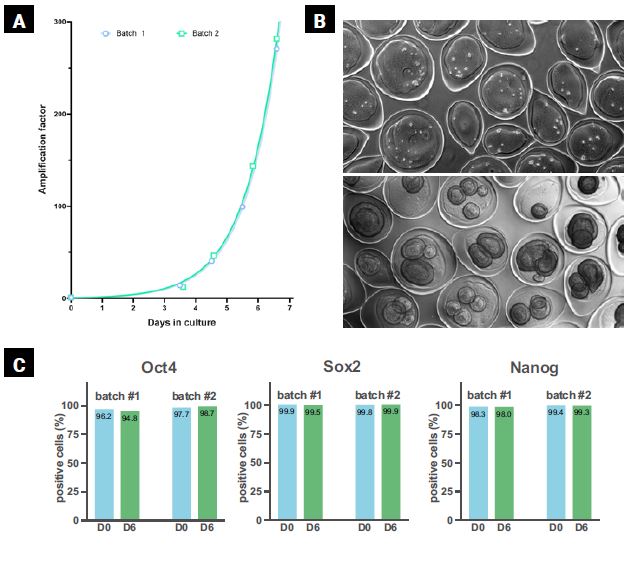

In 2021, just a few months after the commissioning of its first industrial encapsulation device, TreeFrog Therapeutics announced the production of two single batches of 15 billion hiPSCs in 10L bioreactors, with an unprecedented amplification factor of 276-fold within a week. Data demonstrated remarkable reproducibility (95% confidence interval), cell viability (>98.8%) and pluripotency (95% OCT4, 99% SOX2, 98% NANOG). This result contrasts with the best performance described in the literature (Huang et al., 2020), consisting in the 37-fold expansion of 1 billion hiPSC over 6 days in a 10L bioreactor and reporting a significant drop in stemness.

Highly reproducible production of 2 single batches of 15Bn hiPSCs in 10L bioreactors, with unprecedented 276-fold amplification factor per week, and conservation of cell quality (Cohen et al., 2023)

Genomic integrity

As expected, preliminary results assessing the genomic integrity of hiPSCs amplified with C-Stem™ demonstrated the benefits of the lumenized rosette format for the containment of pre-oncogenic mutations over prolonged culture (15-fold fewer pre-oncogenic mutations than in standard hiPSC culture in 2D, and 25-fold less than in hiPSC aggregates). In particular, the high hPSC viability obtained with this technology has demonstrated the capacity to mitigate the pro-survival advantage conferred by 20q11.21 copy number variation. In a more general sense, the limited cell death observed in C-Stem™ may reduce the selective advantage of mutations that affects cell survival, thus positively impacting the safety profile of hPSC populations expanded with the technology.